Have you ever tackled a DIY plumbing project only to find yourself baffled by the array of pipes and fittings at the hardware store? Or perhaps you’ve watched a seasoned plumber effortlessly select the perfect pipe for a job and wondered how they do it.

This guide is here to demystify the world of plastic pipes, specifically PVC and HDPE. By the end of this article, you’ll understand the essential concepts of pipe sizing, including nominal pipe size (NPS), schedule, pressure rating, bend radius, temperature rating, and chemical resistance.

What Is PVC?

Polyvinyl chloride (PVC) is a versatile plastic material widely used in various industries, including construction and plumbing. It is known for its durability, affordability, and ease of installation. PVC pipes in Dubai are a popular choice for sewage, drainage, and irrigation systems.

Due to its excellent chemical resistance, PVC pipes are also used in industrial applications, such as chemical processing and wastewater treatment.

What is HDPE?

High-density polyethylene (HDPE) is another popular plastic material used in various applications, including pipes.

HDPE pipes are known for their high strength, flexibility, and resistance to impact and abrasion. These qualities make them ideal for underground piping systems, gas distribution, and water supply.

HDPE pipes are also used in the oil and gas industry to transport fuels and chemicals. If you’re in the market for HDPE pipe manufacturers in Dubai, you’ll find several reputable companies that produce these high-quality products for various applications.

Key Considerations for Pipe Size Selection

Selecting the right size of pipe for your project is crucial for optimal performance and longevity. To make the right decision, you must consider several factors:

1. Nominal Pipe Size (NPS)

Nominal Pipe Size (NPS) refers to the standard designation for pipe sizes. Take note that NPS does not directly correspond to the actual inside or outside diameter of the pipe. Instead, it’s based on a nominal system that considers factors like wall thickness and manufacturing standards.

For instance, a two-inch NPS pipe might have a slightly larger or smaller actual diameter depending on the pipe schedule. Understanding NPS is essential for selecting pipes that can handle the required flow rate and pressure for specific applications.

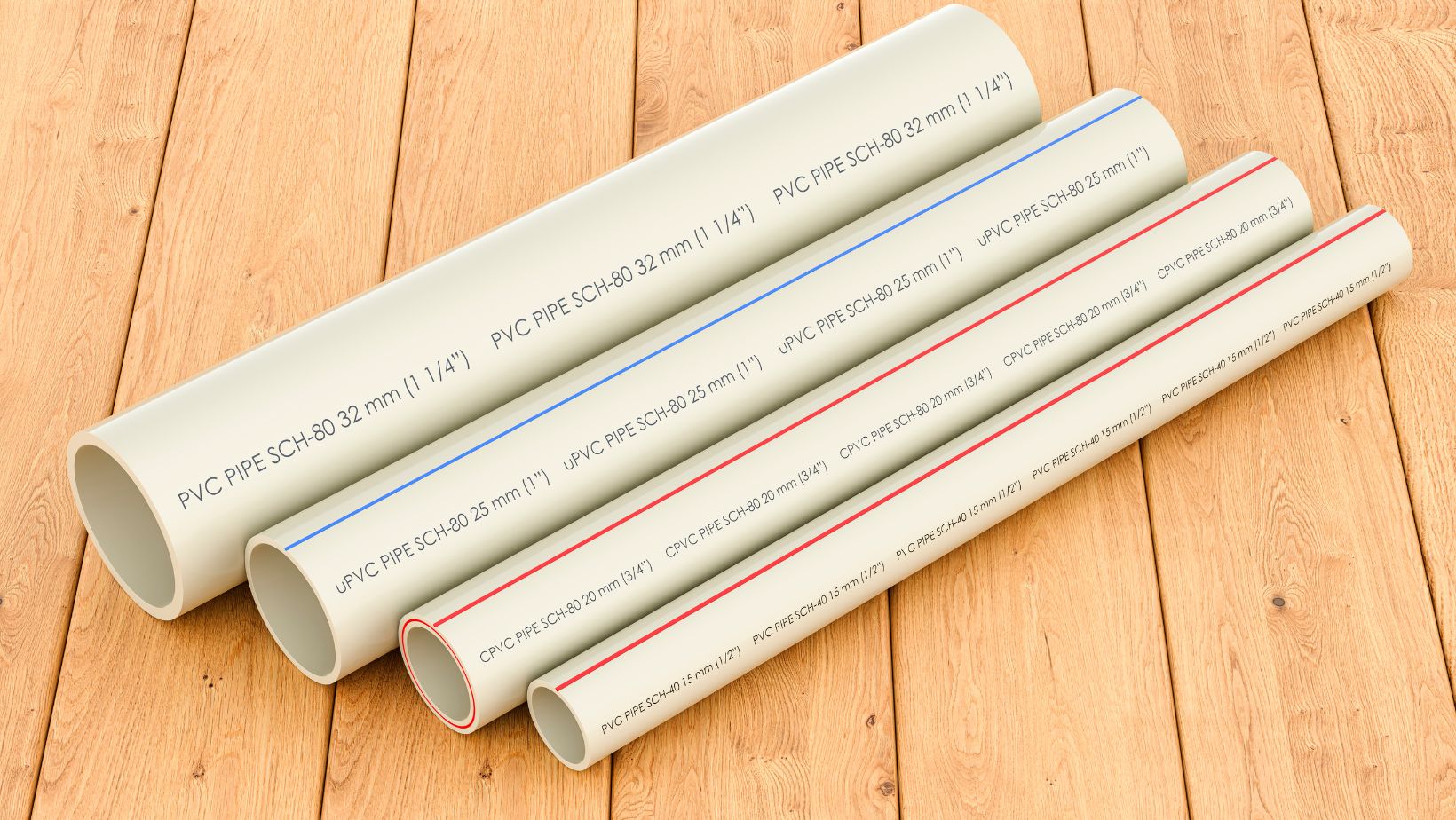

2. Schedule

The pipe schedule indicates the wall thickness of the pipe. A higher schedule number corresponds to a thicker wall. Common pipe schedule options include Schedule 40, 80, and 120.

Thicker walls can withstand higher pressures and temperatures, but they also increase the cost of the pipe. So, when shopping for your supplies, pick a pipe schedule based on the specific requirements of your application. For instance, a high-pressure water line might require a higher schedule pipe to ensure safety and durability.

3. Pressure Rating

A pipe’s pressure rating is the maximum pressure it can withstand without failing. It is measured in pounds per square inch (PSI).

Factors like pipe material, size, schedule, and temperature affect the pressure rating. Make sure you select a pipe with a pressure rating that exceeds your plumbing or water system’s maximum operating pressure.

4. Bend Radius

Bend radius refers to the minimum radius a pipe can be bent without getting damaged.

Different pipe materials have different bend radii. For example, HDPE pipes are more flexible than PVC pipes and can be bent to tighter radii.

Of course, when installing pipes, you must avoid bending them too sharply, regardless of the bend radius. This is because doing so can weaken the pipe and lead to leaks.

5. Temperature Rating

The temperature rating of a pipe indicates the maximum temperature it can withstand without compromising its performance. PVC pipes have specific temperature limitations, especially when exposed to hot conditions for extended periods.

Choose pipes that can handle the temperature fluctuations in your application. For instance, pipes used for hot water systems should have a higher temperature rating.

6. Chemical Resistance

The chemical resistance of a pipe refers to its ability to withstand exposure to various chemicals. PVC and HDPE pipes offer good chemical resistance to many substances, but they may be susceptible to certain chemicals, such as strong acids and solvents.

When selecting pipes for chemical applications, consider the specific chemicals involved and choose pipes made with a compatible material.

For instance, HDPE has a higher resistance to nitric acid at most concentrations than PVC. On the other hand, PVC can handle chlorine better at over 50 ppm (parts per million) than HDPE.

Pipe Size Selection for Different Applications

To select the right pipe for your specific needs, consider the following factors:

Application

PVC pipes are a common choice for residential and commercial water supply systems due to their durability and affordability.

They are also suitable for drainage systems, including stormwater and wastewater.

However, HDPE pipes are usually preferred for gas distribution due to their high strength and resistance to corrosion.

HDPE pipes also perform better in handling corrosive chemicals, making them suitable for industrial applications.

Pipe Size and Schedule

Refer to the table below for guidance on the ideal pipe size and schedule based on different applications.

|

Application |

Pipe Material |

Pipe Size (in inches) |

Schedule |

|

Water Supply |

PVC |

1/2, 3/4, 1 |

40, 80 |

|

Drainage |

PVC |

2, 3, 4 |

40, 80 |

|

Gas Distribution |

HDPE |

1/2, 3/4, 1 |

80, 120 |

|

Chemical Processing |

HDPE |

2, 3, 4 |

80, 120 |

PVC vs. HDPE: Making a Decision

When choosing between PVC and HDPE pipes, always consider your project’s specific requirements. Remember to consult local building codes and heed manufacturer recommendations to ensure compliance and safety.

For complex installations or projects involving specialized applications, it’s best to seek advice from a qualified plumbing or piping expert or engineer.