Reno is the largest city in Northern Nevada, and thousands of cars pass through its streets and roads daily. Therefore, a well-maintained pavement infrastructure is essential to sustaining the dependability and safety of mobility throughout the region, from broad commercial developments to downtown streets.

A successful Reno paving project requires navigating several crucial factors to attain the best performance and value.

This detailed guide will examine ten key factors that might make or break a Reno paving project to ensure a seamless and long-lasting outcome.

Climate Adaptability

Paving projects face a problem because of Reno’s particular environment. Asphalt needs to be able to survive high-temperature swings without cracking or disintegrating too soon. With scorching summers that frequently reach temperatures above 100 degrees Fahrenheit and frigid, snowy winters where nightly lows regularly drop below freezing, this is a challenge.

So, Reno paving projects necessitate careful consideration of the severe weather. To deal with these characteristics, the proper design of the asphalt mix is essential.

Engineering asphalt mixtures accommodate the thermal expansion and contraction caused by repeated heating and cooling cycles. Asphalt binders are selected based on their capacity to maintain elasticity in the face of freeze-thaw cycles.

Durable materials with low absorption properties are prioritized in aggregate selection to stop moisture incursion from causing cracking. Additives can improve a combination’s cohesion, workability, and durability.

Soil Conditions and Subsurface Preparation

Because Reno is located at the foot of mountains, the makeup of the soil beneath paved areas can vary significantly over short distances. In that case, any work would have to start only after a geotechnical investigation of moisture content, bearing capability, and soil conditions.

This will establish if such soils are inappropriate and must be remediated, removed, and replaced to create a solid subsurface foundation.

More preparation measures will also be needed for the expansive clayey soils compared to the free-draining sandy soils normally available in most parts of Reno. Changes in moisture may cause clayey soils to exhibit swelling and shrinking characteristics if not taken care of well, leading to pavement breakages.

Drainage and Slope

Sustaining efficient drainage is essential for pavement resilience and safety in Reno because of the city’s year-round heavy snowfall and rainfall. Small amounts of standing water can seep into joints and fractures, producing hydrostatic pressure that eventually quickens wear. Longevity depends on carefully planning, designing, and building appropriate cross-slopes and drainage conveyances.

Accurate replication of slopes during paving installations is ensured by proper construction that conforms to design elevations. Methods like laser screeding and routine slope assessments support quality control initiatives.

Traffic Volume and Load Considerations

Proper material and structural sections should be selected considering the expected traffic volumes and load to which the pavement will be subjected. Where the volume is high, a full-depth asphalt or concrete pavement would be of greater thickness, needing thick full-depth asphalt or concrete pavement in these cases.

For example, the pavement subjected to regular, heavy truck traffic can be designed to carry over 8 tons per axle when subjected to normal passenger car loads of 2-4 tons. This will emphasize the pavement reinforcement via geogrids or geotextiles so that the load can spread out to even larger areas of the surface and not cause accelerated fatigue cracking.

Residential streets or smaller business lots that handle light passenger autos may need less structural depth.

Material Selection and Quality

The top priority of any successful Reno Paving Project should be a good material selection. The mix used should be engineered to provide resistance to skidding, environmental factors like UV radiation and oxidation, and durability.

Besides, performance consistency and reliability must be exercised in the aggregate, binder, and other components with quality assurance.

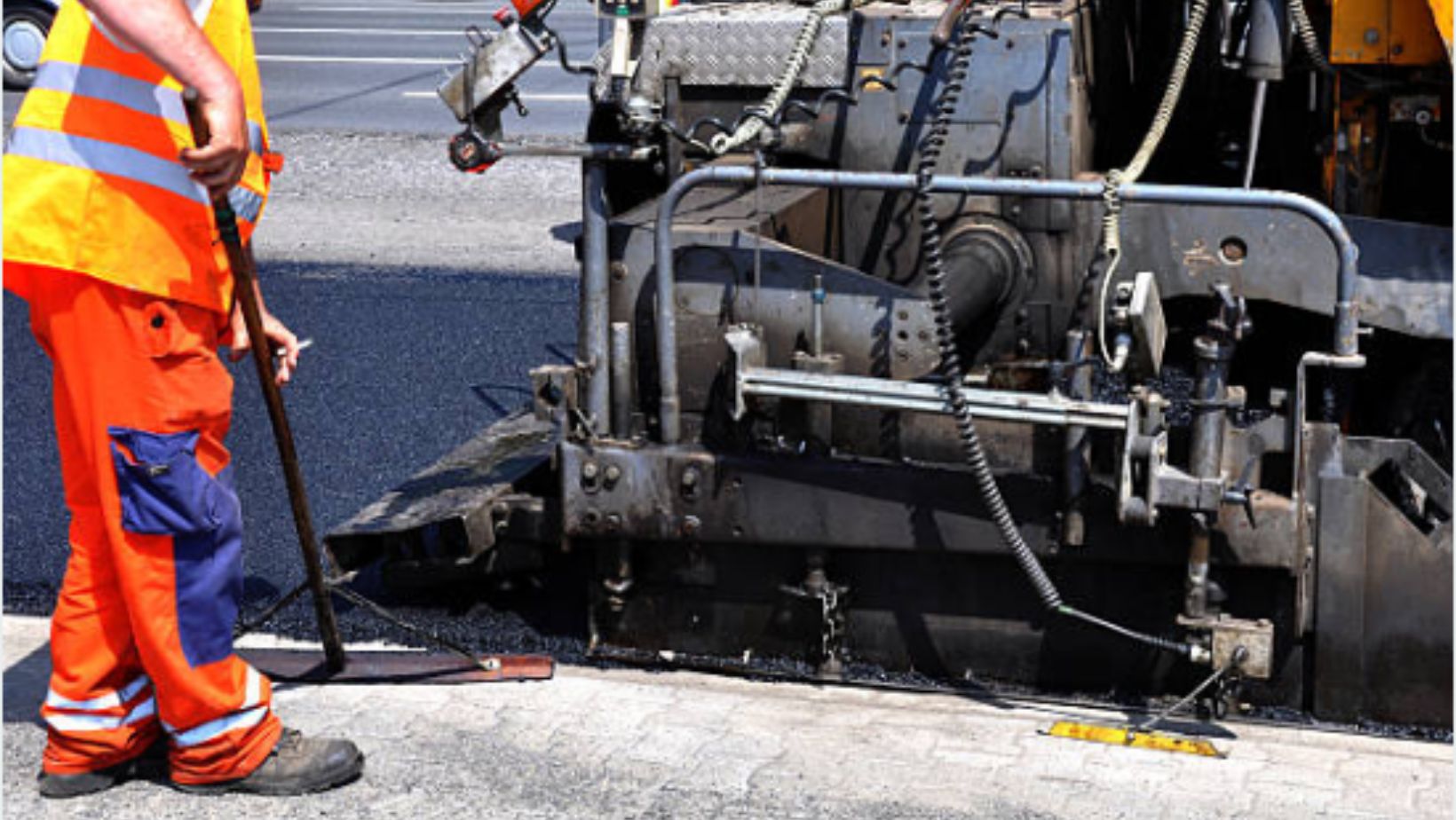

Proper Compaction and Installation Techniques

The quality of the finished paved surface, the right compaction, and installation methods determine a smooth, uniform, long-lasting surface. Always use experienced professionals in your Reno paving project to ensure that the poured asphalt is compacted to the right density, temperature, and thickness.

Even the attention to detail in the installation procedure can contribute much to the longevity and performance of the paved area.

Maintenance and Repair Considerations

Sooner or later, even the best-laid and constructed pavements in Reno succumb to their demands on wear and tear. Crack sealing coating should include periodic inspections and pothole repair as part of a good Reno paving maintenance program.

All these activities enhance the paved surface’s life and reduce its costs for replacement or reconstruction.

Accessibility and Compliance

As in any city, Reno’s paving projects must comply with accessibility standards and regulations, such as the Americans with Disabilities Act (ADA). Proper slope, ramp design, and tactile warning surfaces are essential for ensuring universal access and safety for all users, including those with disabilities or mobility challenges.

Sustainability and Environmental Impact

Reno paving projects’ sustainability and environmental impact must be considered as environmental concerns continue to rise.

Recycled materials, eco-friendly paving methods, and trash reduction strategies help lower the project’s carbon impact and protect Reno’s natural resources and beauty.

Experience and Expertise

Finally, the success of any Reno paving project hinges on the experience and expertise of the contractors involved. Choosing a reputable and experienced paving company with a proven track record in the Reno area can significantly improve the project’s quality, efficiency, and overall success.

Professional contractors deeply understand Reno paving projects’ unique challenges and requirements, allowing them to anticipate and mitigate potential issues before they arise.

Closure

Successful Reno paving projects require a comprehensive approach that considers many factors, from climate adaptability and soil conditions to material selection, installation techniques, and environmental impact.

Property owners, developers, and contractors can ensure that their Reno paving projects meet and exceed expectations by carefully addressing these ten key considerations.